What are Elastomeric Materials classified to?

- Condensation silicones

- Addition silicones

- Polysulfide

- Polyether

When was condensation silicones discovered?

1955

What was the first silicon impressions found?

Condensation silicones

What is the alternative name for condensation silicones?

Conventional silicone

What is condensation silicon mainley used for?

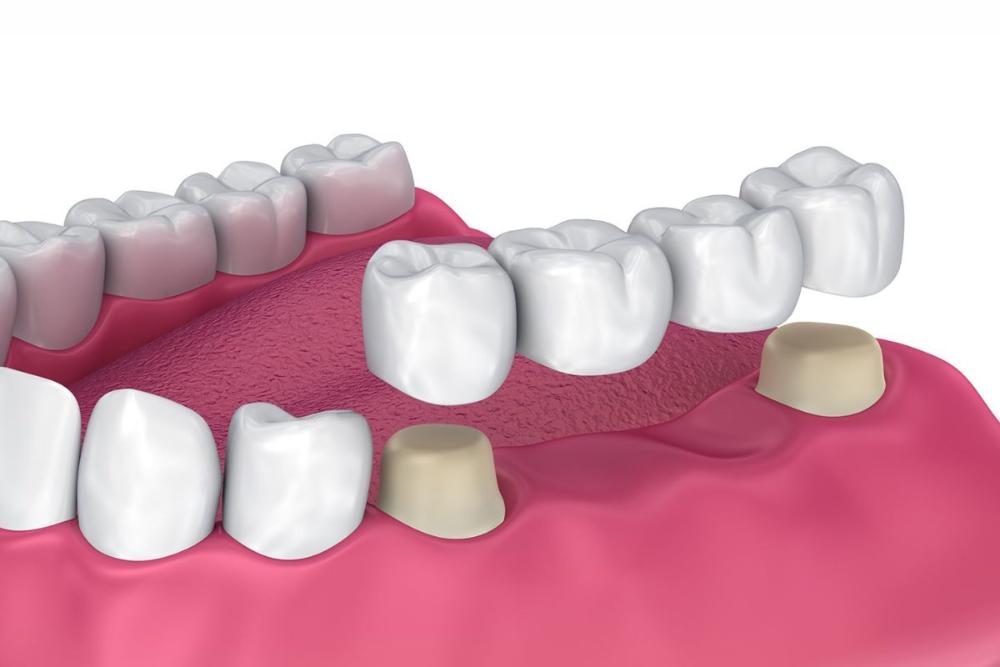

For fixed partial dentures

What is the mixing time for condensation silicon?

45sec

What is the mixing time for addition silicon?

45sec

What is the mixing time for polyether?

30sec

What is the working time for condensation silicon?

2-4min

What is the working time for addition silicon?

2-4min

What is the working time for polyether?

3min

What is the setting time for condensation silicon?

6-8min

What is the setting time for addition silicon?

4-6.5min

What is the setting time for polyether?

6min

What is the relationship between condensation silicon with humidity and temperature?

The setting time of condensation silicon decreases with the increase of temperature and humidity

What is the dimensional change of condensation silicon after 24h?

0.60%

What is the dimensional change of addition silicon after 24h?

0.15%

What is the dimensional change of polyether after 24h?

0.24%

How much time should you wait before you pour the condensation silicon?

It should be poured immediately

What is the reason for the dimensional change in condensation silicon?

Because of shrinkage due to loss of ethyl alcohol

How much is the tear strength of condensation silicon?

3000gm/cm

How much is the tear strength of addition silicon?

3000gm/cm

How much is the tear strength of polyether?

3000gm/cm

How long is the shelf life for condensation silicon?

2 years

How long is the shelf life for addition silicon?

1-2 years

How long is the shelf life for polyether?

More than 2 years

Name the properties of condensation silicon?

Other than the mixing time, shelf life, dimensional change and tear strength it has:

- Decrease in setting time due to higher temperature or humidity

- Excellent detail reproduction

- Pleasent tase and smell

- Its hardness increases overtime

Which one is stiffer and harder:

A)condensation silicon

B)polyether

C)A and B are the same

Condensation silicones because its hardness increases overtime

How do you control the viscosity of condensation silicon and polyether?

Their viscosity depends on how many inert fillers(they are materials you add that modify the viscosity of impressions but don't take part in the chemical reaction) You add

Name the advantages of using condensation silicon?

- Adequate working & setting time.

- Pleasant odor & no staining.

- adequate tear strength

- Better elastic properties on removal than polysulfide.

- Less distortion on removal.

Name the disadvantages of using condensation silicon?

- Poor dimensional stability if wasn't poured immediately

- Putty-wash(Which is when you put a viscous material in the bottom of the impression mold for the overall shape and a less viscous material on top of it to catch the finer details) is sensitive on it

- More expensive than polyether

Which one is more expensive:

A)condensation silicon

B)polyether

C)A and B are the same

B

When is the addition silicon made?

1975

Which one have better properties overall?

A)condensation silicon

B)polyether

C)addition silicon

D)they are the same

C

What is the alternative name for Addition silicon?

Poly vinyl siloxane

How long can addition silicon last dimensionally stable?

It can stay dimensionally stable even after 1 week

Name the properties of addition silicon?

Other than the mixing time, shelf life, dimensional change and tear strength it has:

1-good detail reproduction

2-extremly hydrophobic

3-can be used to duplicate cast models(models that have already been used to record the patient's mouth details)

4-low flexibility

5-sulfur can cause retardation(increase) of setting time or even no polymerization(mixing between base and catalyst)

6-expensive

How long should you wait before putting gypsum and dies on addition silicons? And why?

30mins, because they release H2 on setting

What is the most dimensionally stable elastomeric impression material?

Addition silicones

What is the problem with the dimensionally stability of addition silicon?

They have inadequate dimensional stability when it comes to maintain their shape during production of working cast thats why they are syringed in the place on to the tooth for accuracy

When was polyether discovered?

1965

Where was polyether discovered?

In germany

What is polyether used for generally?

For a few type of teeth impressions that doesn't have deep undercuts because of their hardness and short working time

What are the properties of polyether?

Other than the mixing time, shelf life, dimensional change and tear strength it has:

- The sulfonic ester causes skin reaction

- Good dimensional stability

- Decreased flexibility by 3%

- Can cause allergy

What are the advantages of polyether?

- short working & setting time

- proven accuracy

- adequate tear strength

- long shelf life

- less distortion on removal

- Good dimensional stability

What are the disadvantages of polyether?

- Can't deal with undercuts due to stiffness

- Expensive

- Can't be re-poured becuase of its stiffness

What were Elastomeric materials called in the first place?

Synthetic rubber or rubber impression materials

What are elastomeric impression materials mostly used for?

- Removable partial dentures

- To take impression for edentulous(teethless) mouth to make complete dentures

- For dental implants

- For bite registration

- SPECIFICALLY Polyether is used for Border moulding

How are elastomeric impression materials generally supplied?

As two separate pastes:

- Base paste

- Catalyst paste

How are putty(high viscosity) elastomeric impression materials generally supplied?

In jars

What are the general properties of Elastomeric impression materials?

Elastomeric impression materials:

- Produce accurate surface details bc of their low viscosity

- are hydrophobic(except polyether)

- could be poured multiple times

- Have high coefficient of thermal expansion

- Experience dimensional changes after setting

- Have good adhesion(as long as you use adhesives too) that will decrease dimensional changes

- Excellent tear strength which makes them useful even in the form of thin sheets

Should the mouth be dried or not before using elastomeric impression materials?

Yes the mouth should be dried bc you need good flow since elastomeric impression materials are hydrophobic

What causes dimensional changes in elastomeric impression materials?

- Curing shrinkage(shrinkage while setting) because of loss of the impressions by-product

- SPECIFIC TO polyether that absorbs water which makes it expand

What by-product in condensation silicon is lost while sitting?

Alcohol

What by-product in polysulfide is lost while sitting?

Its volatile accelerators

When should you pour elastomeric impression materials?

After elastic recovery but before dimensional changes are set

What is the number one thing that determines the properties of elastomeric impression materials?

The amount of filler that is added to the pastes

According to their viscosity, which type of elastomeric impression material is more accurate? Why?

Heavy-bodied viscosity type of elastomeric impression materials bc it has more dimensional stability due to lower thermal contraction

What are the ways of mixing elastomeric impression materials?

By:

- Hand

- Static automixing

- Dynamic mechanical mixing

How could you prepare elastomeric impression materials?

- Get equal lengths of base and catalyst paste

- Mix them untill there is no streaks of colors are left

- Coat the tray with two layer of adhesive materials

- Load the tray with the impression material using either a syringe or directly in the tray

What is the first elastomeric impression material?

Polysulfide

When was polysulfide introduced?

1950

What are other names for polysulfide?

Mercaptan/ thymol

What is the color of the Base paste of polysulfide?

White

What is the color of the catalyst paste of polysulfide?

Grey or Brown

How long is the working time for polysulfide?

4-7min

How long is the setting time for polysulfide

7-10min

How long would the polysulfide need to set if it was in colder ambient atmosphere?

It could be workable for as long as 16min

Does water accelerates or acts as a retarder for the setting reaction of polysulfide?

It accelerates the setting of polysulfide

What are general properties of polysulfide?

- Accurate surface reproduction

- Has the highest permanent deformation

- Hydrophobic

- Good tear strength

- Unpleasant smell and taste

- Mostly used for crown and bridge impressions and not used so much for other uses

How much is the dimensional change of polysulfide after 24h?

0.4%

How much is the permenant deformation of polysulfide?

3-5%

How much is the flexibility of polysulfide in percentage?

7%

How much is the space needed for elastic recovery between polysulfide and the tray?

2mm

How long is the shelf life for polysulfide?

2 years

What elastomeric impression material has the highest permenant deformation?

Polysulfide

Which one is less hydrophobic condensation silicon or polysulfide?

Polysulfide

What are the advantages of polysulfide?

- Long working time

- Good accuracy

- High tear strength

- Long shelf life

- Inexpensive

What are the disadvantages of polysulfide?

- Must be poured with dental stone immediately

- Potential for significant distortion

- Bad taste and smell

- Re-pouring makes it less accurate

Do elastomeric impression materials shrink or expand with high temperature?

Expand becuase of high coefficient of thermal expansion